Magnetically Coupled Gear Pumps

Magnetically Coupled Gear Pumps

What Is a Magnetically Coupled Gear Pump?

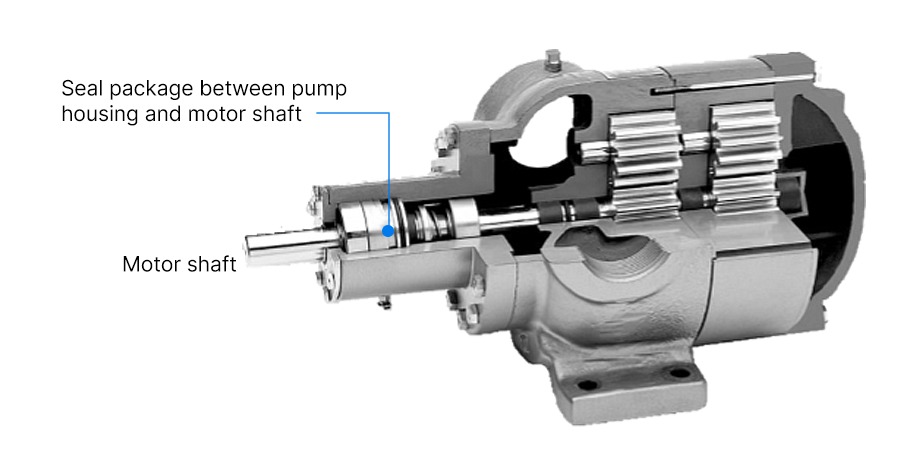

Traditional external gear pumps utilize a motor shaft which is directly coupled to a driving gear within the pump. To make this coupling, the shaft must pass through a sliding seal. The typical life-limiting component in a direct drive pump is the seal. Regardless of seal type and quality, the seal will wear and eventually leak. Magnetically coupled gear pumps avoid the life-limiting seal by using a magnetic coupling to transfer torque into the pump. This establishes a hermetic seal while still coupling the motor to the driving gear.

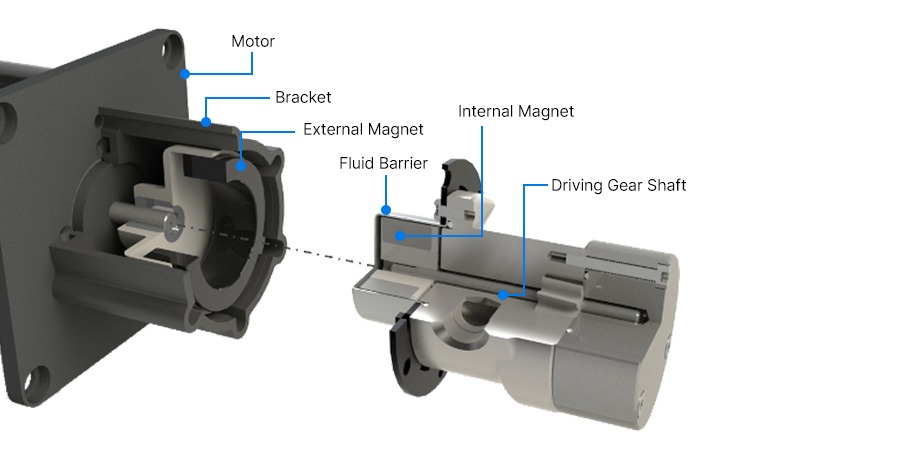

Traditional Magnetic Coupling

Traditional magnetic couplings have a magnet internal to the pump which is attached to the driving gear. The magnet can be a simple ferrite magnet or, for higher coupling strengths, a magnet made from rare earth metals. Typically, the magnet is encased in a metal or plastic jacket to prevent contact with the pumped fluid. The jacket also provides coupling to the driving gear. A thin metal barrier separates the fluid from the atmosphere. A second magnet, attached to the motor, is external to the fluid barrier and is magnetized to form a coupling with the internal magnet. The external magnet can be made from ferrite or rare earth alloys. Magnetic strength decreases with distance squared, making it critical to minimize the distance between the magnets. This requires precision machining and assembly for an efficient design. Balance and runout of the internal magnet is critical to maximize the life of internal bearings and for smooth, quiet operation.

Advantages

• Eliminates sliding seal, thereby extending pump life and reducing frictional drag

• Allows the use of any motor type and size

• Isolates the heat-generating motor from the pumped fluid

• Capable of very strong magnetic coupling when both internal and external magnets are rare earth alloys.

Disadvantages

• Addition of the magnetic coupling increases overall size of the pump assembly.

• Adds costs due to additional magnets and brackets

Direct Magnetic Drive

The traditional magnetic coupling evolved into a direct magnetic drive. This drive uses the pump’s internal magnet as the rotor for a brushless DC (BLDC) motor. This method eliminates the stand-alone motor, extra brackets and external magnet. The resulting product is a compact, inexpensive, hermitically sealed pump. To make an effective BLDC motor in this configuration, the internal magnet must be made from a rare earth metal alloy. However, the enclosure around the magnet and the barrier between the fluid and atmosphere can be the same as a traditional magnetic coupling.

Advantages

• Eliminates sliding seal, thereby extending pump life and reducing frictional drag

• Compact design allows placement in tight spaces

• Fewer components required, lowering pump manufacturing cost

• Longest life because there are no motor ball bearings to wear out

Disadvantages

• There are power and input type limitations based on the pump supplier’s product portfolio.

• Heat-producing coils are situated close to pump, potentially adding heat to the fluid system. This is typically a minor effect and only of concern for small, closed loop systems.

Related Products

Reach Out Today

Contact us to get a free quote, your project will meet a right solution with us.

Tell Us What You Need

Tell us as specific as possible of your needs, provide the drawing, reference picture and share your idea to us.

Get Solution & Quote

We will work on the best solution according to your requirements, and quote will be provided within 24 hours.

Approve Mass Production

We will start mass production after approval and deposit, and we will handle the shipment and future after-sale service.