Understanding Diaphragm Micro Pumps: Applications, Advantages, and How They Work

Understanding Diaphragm Micro Pumps: Applications, Advantages, and How They Work

In the world of precision fluid handling, diaphragm micro pumps are a reliable and versatile solution. These compact pumps are widely used across industries due to their accuracy, chemical compatibility, and ability to handle both gas and liquid media. Whether you’re developing a medical device, analytical instrument, or consumer appliance, diaphragm pumps offer a powerful combination of performance and reliability.

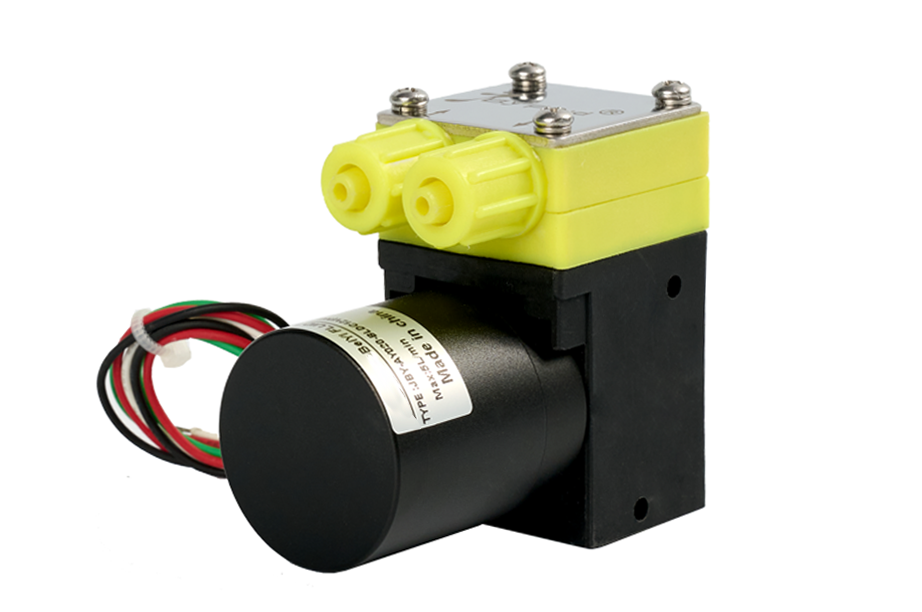

What is a Diaphragm Micro Pump?

A diaphragm micro pump is a positive displacement pump that moves fluids using a flexible diaphragm that expands and contracts. The motion is typically driven by a motor or piezoelectric element, creating a vacuum that draws in and pushes out small amounts of fluid or gas. This design ensures precise flow control without direct contact between the fluid and mechanical components.

Key Advantages of Diaphragm Micro Pumps

1. Medical and Healthcare Devices

Infusion pumps

Wound therapy systems

Portable blood pressure monitors

Nebulizers and respiratory aids

2. Environmental Monitoring and Analytical Instruments

Gas sampling systems

Water quality testing devices

Air analyzers

Lab-on-chip platforms

3. Industrial and Automation Applications

Fuel cell systems

Inkjet printing

Chemical dosing

Smart agriculture equipment

How Diaphragm Micro Pumps Work

The basic operation involves the repeated movement of a diaphragm to displace fluid:

Intake Phase – As the diaphragm pulls back, a vacuum is created in the chamber, drawing fluid or gas through the inlet valve.

Compression Phase – The diaphragm moves forward, compressing the chamber contents and pushing them through the outlet valve.

Check Valves – Inlet and outlet valves ensure unidirectional flow, preventing backflow and maintaining consistent performance.

This mechanism allows diaphragm pumps to operate smoothly, quietly, and with high control over volume per cycle, even at micro-scale.

Why Choose Diaphragm Pumps Over Other Types?

Compared to gear or peristaltic pumps, diaphragm micro pumps offer:

No shear stress on fluid, suitable for delicate biological media

Lower maintenance, due to simple construction and fewer moving parts

Quiet operation, beneficial in medical and consumer settings

Precise dosing and metering, even in variable pressure systems

Considerations for Selecting a Diaphragm Micro Pump

When choosing a pump for your system, evaluate the following:

Flow rate and pressure range

Voltage and power requirements

Fluid characteristics (corrosiveness, viscosity)

Operating environment (temperature, humidity, exposure)

Certification or regulatory needs (for medical or food-grade use)

Conclusion

Diaphragm micro pumps are an essential component in today’s compact and high-performance devices. Their ability to move fluids accurately and reliably—without leakage or contamination—makes them a top choice for engineers and product developers in a range of sectors.

If you’re looking for a trusted supplier of diaphragm micro pumps with extensive OEM/ODM capabilities, we’re here to help. Contact us today to explore how our pumps can add value to your system.

Related Products

Reach Out Today

Contact us to get a free quote, your project will meet a right solution with us.

Tell Us What You Need

Tell us as specific as possible of your needs, provide the drawing, reference picture and share your idea to us.

Get Solution & Quote

We will work on the best solution according to your requirements, and quote will be provided within 24 hours.

Approve Mass Production

We will start mass production after approval and deposit, and we will handle the shipment and future after-sale service.