Understanding More About Diaphragm Pumps

Understanding More About Diaphragm Pumps

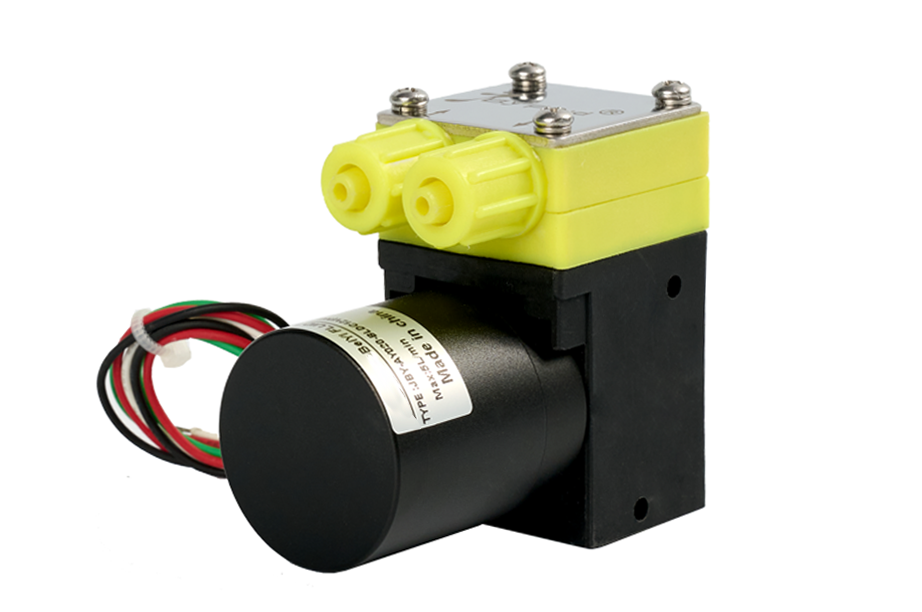

What Is a Diaphragm Pump?

A diaphragm pump is a type of positive displacement pump that moves fluids using a flexible diaphragm in combination with one-way valves. As the diaphragm moves back and forth, it creates variable chamber volumes, drawing fluid in and pushing it out. Unlike rotary pumps, diaphragm pumps operate without sliding seals or internal lubrication, making them suitable for handling corrosive, abrasive, or sensitive fluids.

This seal-less pumping method is particularly important in industries where fluid purity, chemical resistance, or leak-free operation is required. Common applications include medical devices, chemical dosing systems, laboratory instruments, and small-scale industrial equipment.

Operating Principle

In a typical design, the diaphragm is actuated either mechanically, pneumatically, or electrically:

Mechanical drive: A motor-driven eccentric or lever directly flexes the diaphragm.

Air-operated drive: Compressed air alternately pushes the diaphragm, creating suction and discharge cycles.

Electrically driven: A solenoid or motor-driven mechanism provides the reciprocating motion.

Check valves on both sides of the diaphragm control the fluid path, ensuring unidirectional flow. This simple but reliable mechanism allows precise fluid transfer with minimal wear on moving parts.Wound therapy systems.

Advantages

Leak-Free Operation: No sliding seals, reducing the risk of leakage even with corrosive or hazardous fluids.

Self-Priming: Can run dry for short periods and easily handle viscous or gaseous fluids.

Versatility: Suitable for water, chemicals, air, and even slurries.

Low Maintenance: Fewer mechanical parts in contact with fluid reduce wear and servicing needs.

Safe for Sensitive Applications: Gentle pumping action makes it ideal for medical, food-grade, or lab use.

Disadvantages

Flow Pulsation: The reciprocating action produces pulsating flow, which may require dampeners in precision systems.

Limited Pressure/Flow Capacity: Compared with centrifugal or gear pumps, diaphragm pumps generally handle smaller volumes.

Diaphragm Wear: Over time, the flexible diaphragm can fatigue and require replacement.

Modern Developments

Recent advancements in diaphragm pump technology address traditional limitations:

Brushless DC Motor Integration: Provides precise control, compact size, and long service life.

Advanced Materials: Diaphragms made from PTFE or composite polymers improve chemical resistance and lifespan.

Miniaturization: Micro diaphragm pumps now serve portable medical devices, analytical instruments, and consumer electronics.

Noise Reduction: Optimized valve and chamber designs provide quieter operation, important for lab and home-use applications.

Conclusion

Diaphragm pumps combine simplicity, reliability, and adaptability, making them indispensable across multiple industries. While they may not match the flow rates of centrifugal pumps or the precision of gear pumps, their leak-free design, chemical resistance, and ability to handle a wide range of fluids make them one of the most trusted pump technologies today.

For OEMs and system builders, diaphragm pumps offer an ideal balance between performance, safety, and cost-effectiveness.

Related Products

Reach Out Today

Contact us to get a free quote, your project will meet a right solution with us.

Tell Us What You Need

Tell us as specific as possible of your needs, provide the drawing, reference picture and share your idea to us.

Get Solution & Quote

We will work on the best solution according to your requirements, and quote will be provided within 24 hours.

Approve Mass Production

We will start mass production after approval and deposit, and we will handle the shipment and future after-sale service.