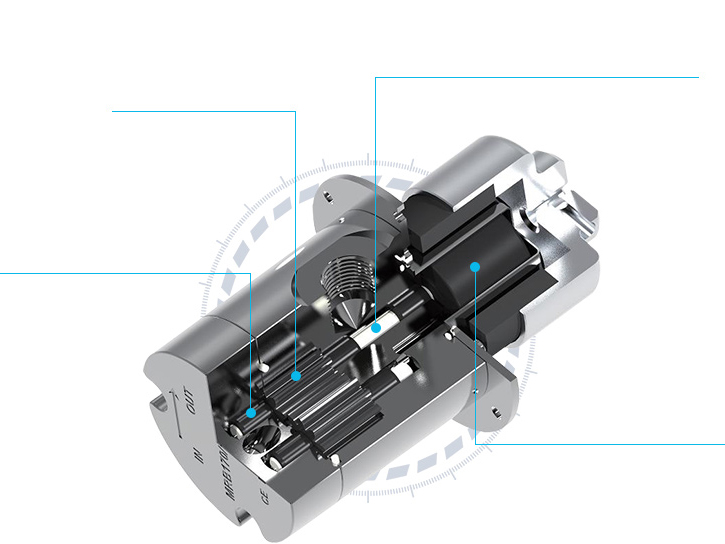

Why choose magnetic driven gear pump?

Key advantages include:

• Leak-free design – Magnetic coupling completely isolates the drive from the fluid chamber, preventing leakage and improving safety

• High-precision output – Delivers steady, low-pulsation flow of low-viscosity liquids with excellent accuracy

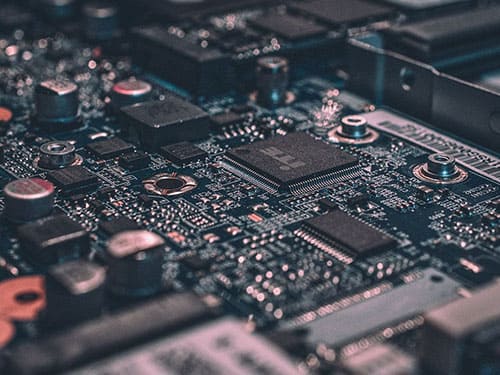

• Corrosion resistance – Components made from high-performance plastics (PEEK, PTFE) or ceramics, ideal for acids, alkalis, and chemical fluids

• Compact and efficient – Suitable for systems with limited space, while offering high pressure resistance and long service life

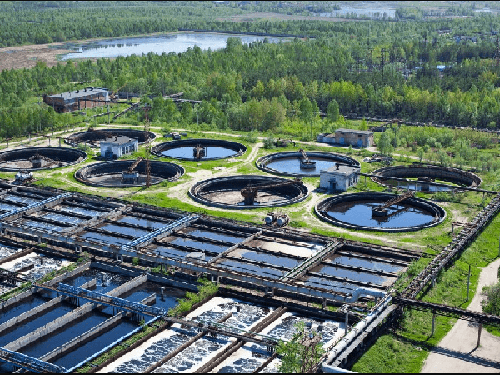

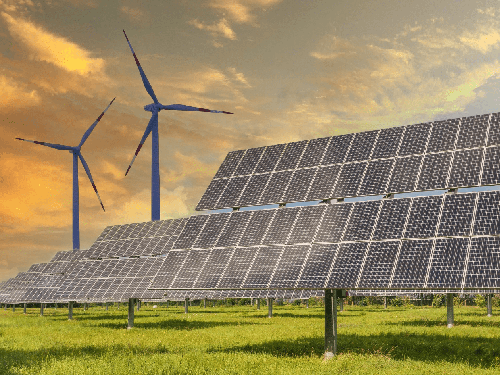

Magnetic gear pumps are widely used in fine chemical processing, environmental systems, laboratory instruments, semiconductor cleaning equipment, and other advanced fluid systems requiring leak-free, maintenance-free performance.

Product Futures

Need a custom solution?

Let’s make it simple.

Professional OEM/ODM services to match. From function to design, we offer fast and flexible customization to meet your exact needs.

Customization Options

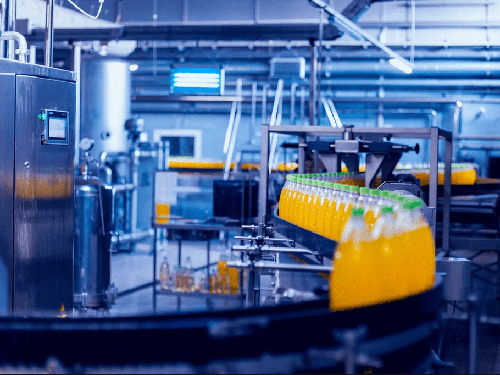

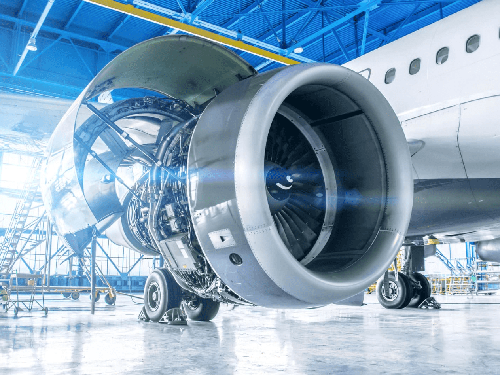

Applications Across Industries

Our miniature pumps deliver reliable performance across a wide range of industries — from medical and automotive to environmental and industrial applications.

Reach Out Today

Contact us to get a free quote, your project will meet a right solution with us.